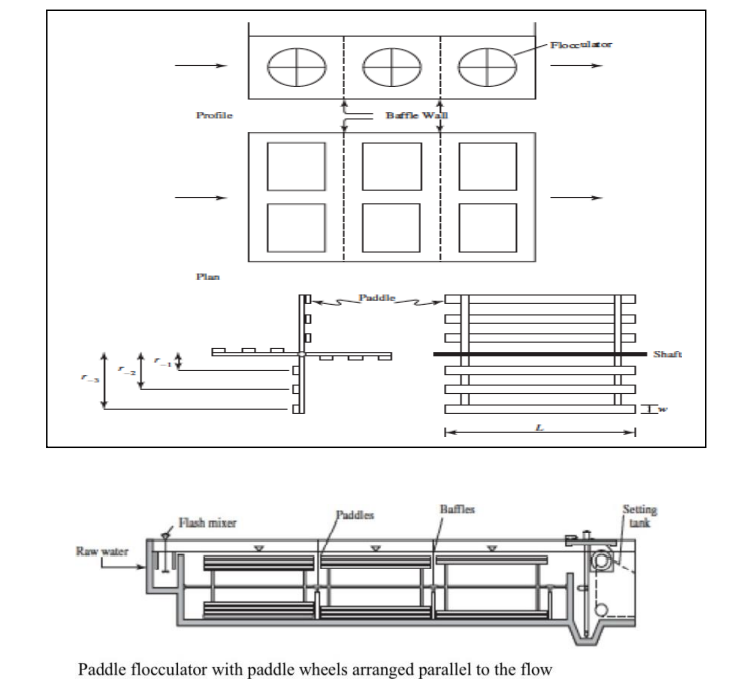

Typical horizontal paddle wheel flocculator. Paddle wheel flocculators rotate at low rpm and dissipate energy into water.

Design Criteria For Paddle Wheel Flocculator Chegg Com

48 minutes Gt 25 s-1 x 46.

. Based on the configuration the paddle flocculator can be classified as Vertical paddle-wheel flocculator and Horizontal paddle-wheel flocculator. Horizontal flocculator drives can have a dry well requiring a wall penetration or a wet well arrangement. Shafting and paddle supports - epoxy coated carbon steel chroming or 304316 SS.

They enhance the process of flocculation by promoting agglomeration of the flocs. 48 minutes x 60 sminute Gt 69 720 between 50 000 -100 000 OK velocity of the water v 75 of the maximum peripheral velocity The distance traveled is. Figure 34 Horizontal Paddle Flocculator Design An 2017 Bottom left.

Application Description Most drinking water is stored in surface reservoirs where the water picks up materials such as dirt and plant matter. Big and dense flocs are desirable - this can be obtained by. Horizontal Paddle Flocculators This is a traditional flocculator design for water treatment appli-cations.

Flocculator Design Overview Analysis of hydraulic flocculators Ratio of maximum to average energy dissipation rate Inefficiency of energy use due to nonuniformity of energy dissipation rate The great transition at Ø 55 Flocculator Design Head loss collision potential residence time. Amwell paddle wheel flocculators provide engineers and water treatment facilities with well designed well crafted flocculator systems engineered for long life and minimal maintenance. Configurations and Materials of construction include.

Design criteria for paddle wheel flocculator Horizontal shaft paddle wheel flocculators are to be used for flocculation in a water treatment plant with a design flow rate of 130 MLd. Amwell paddle wheel flocculators provide engineers and water treatment facilities with well designed well crafted flocculator systems engineered for long life and minimal maintenance. Large G and small t produce small but dense flocs.

Flocculation Design Equations Calculator Wastewater Water Treatment Systems Formulas. 11 Tapered flocculation may be obtained by varying. Vertical paddle wheel flocculators consist of a drive assembly containing a gear motor stainless steel drive stand shaft coupling shaft collar thrust bearing and drive shaft which connects.

Josh Franks PE Senior Application Engineer from JMS talks about the cur. On each paddle wheel having a common horizontal shaft. Power input is varied by changing.

Design criteria for Mechanical flocculator are furnished below. Bilge Alpaslan Kocamemi. MRIs Paddle Wheel Flocculator provides a unique advantage.

Solving For Paddle Area. This enables a varied paddle configuration and achieves the use of a range of G-values which in turn advances the ability to control flocculation outcomes. The flexibility to install a number of flocculators on a single drive.

Amwell flocculators are available in your choice of horizontal or vertical configurations for all water applications. According to the Table land2 Design a horizontal paddle wheel flocculator. The dimensions of the stage The diameter of the impeller assume a turbine having three pitched blades with camber a foil Tablel-Flow discharge for each student Qmd student.

Using robust components and a complete stainless steel design MRIs Vertical Paddle Wheel Flocculators will create optimal floc for years to come. 2 2 3 v3 g C A v P CDA D γ. 3.

Top Bottom left. Paddles revolve around a horizontal shaft driven by a motor and reducer through a chain and sprocket arrangement. Mechanical paddle mixers in a flocculation basin with a detention time of 20 to 60 minutes are widely used in practice.

Make the following design decisions for the second compartment in each flocculation train. Paddle Wheels Design The power imparted by paddle wheels is given by the following. So determine the following design features for the first stage in each flocculation train.

P power t VQ 51 780. CD Coefficient of drag A Paddle area ft2 m2 ρ density of the liquid ρ γg v Velocity of the paddle relative to water fps mps g gravity 3217 ftsec2 981 ms2 Table 83 gives values for drag coefficient. The total detention time HRT for flocculation is to be 25.

Low tip speeds create a gentle rotary mixing which promotes floc devel-opment. JMS Mega-FLOCS Paddle Wheel Flocculators are available for all of your flocculation needs. Solve for velocity.

Example paddle flocculator design Example paddle flocculator design Two such paddle wheels will be on the shaft in each stage of flocculation compartment. FLOCCULATOR 3 1 2 Q HLG 144 f 2 t n. Water is pumped from the reservoir into a basin about 8 deep 15 wide and 80 to 100 long.

Amwell flocculators are available in your choice of horizontal or vertical configurations for all water applications. Mechanical flocculators consist of revolving paddles connected to horizontal or vertical shafts driven by electric motor. Top view of the unit showing 2 parallel trains and each train is to be made of 5 wheels compartments in series.

JMS can design and manufacture 3 styles of Flocculators. 9 ft 312 x 106 gpd x x 1440 minutesday t 46. Power dissipated P.

Small G and large t produce big but light flocs. Typical G-t for flocculation is 2 x 10 4 - 10 5. Math Geometry Physics Force Fluid Mechanics Finance Loan Calculator.

Use 3 paddle boards per arm with leading edges located at 067 133 and 20 m from the shaft centerline. Flocculation is to be designed with two parallel trains and each train is to be made of five compartments in series. Cross section and close up of each wheel showing each one has 4 arms with 3 paddle boards on each arm.

To remove these materials a method called flocculation is used. Watch this JMS Presentation on Types of Flocculators for Water Treatment Plants. Design of Rapid mixing Coagulation CHAPTER.

Flocculation calculator solving for paddle area given drag coefficient.

Paddle Wheel Flocculators Jms Mega Floc

Mri Vertical Paddle Wheel Flocculators The Most Robust Design For Consistent Floc Production Mri Meurer Research

Mri Horizontal Paddle Wheel Flocculators Strongest And Most Versatile Floc Production System Mri Meurer Research

Solved Design A Paddle Flocculator With The Following Chegg Com

Table Drinking Water Climate Policy Watcher

Mri Horizontal Paddle Wheel Flocculators Strongest And Most Versatile Floc Production System Mri Meurer Research

0 comments

Post a Comment